|

|

|

|

Performance

- Developed by DuPont® and the Crowell

Corporation

- Adheres to itself, not your product

- Strong lightweight package

- Non-abrasive and moisture resistant

- Wide variety of the lines allows for

product-specific applications

- Tear and puncture resistant outer shell

made of paper, linerboard, or film

- Provides an airtight package

- Series offer either highly flexible or

rigid packaging alternatives

- Self-mailing capabilities

- Cushioning provided by Microfoam® which

has high cling, low slip, low static characteristics

- Leaves no residue like most adhesives

|

|

Easy to use

- Cohesive instantly seals by the use

of pressure, not heat

- Eliminates the need for additional

fasteners such as tape or staples

- Creates a secure, tamper-evident

pack

- Self-sealing capacities similar to a

padded mailer envelope

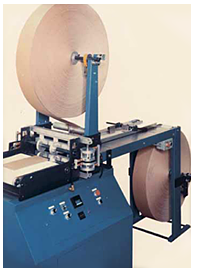

- Apply by hand or with available

automated equipment

Laminates

offered

- Cro-nel® & Nyvel® offered

in custom roll widths

- Available in either large rolls to

minimize roll changeovers or small to avoid space constraints

- Cro-nel® Plus offered in custom

roll widths and perforations

- Nyvel® & Film combination

reveal products to consumers for confirmation and advertising

Reduce Damage

- By incasing your product, leaves no

exposed surfaces

- Gently locks your product in place,

reducing movement during shipping or handling

- Eliminates surface damage

- Provides critical corner

protection

- Remains intact through out

shipping

- Does not settle like peanuts or allow

movement like air-pack

|

|

Surface Protection

- Eliminates surface damage by completely

encasing your product

- Surface protection acts as a protective

shell to your product

- Air tight enclosure protects from dirt,

grease, and moisture

- Interleaving of products remains intact

throughout transit reducing rub damage

Cushioning provided by

Polypropylene Microfoam®

- Microfoam® cushioning provides high

cling, low slip protection to Cro-nel® Products

- Microfoam® in combination with our

specially formulated cohesive coatings eliminates static

- Microfoam® will allow coating directly

on the foam unlike PE foam.

- Microfoam® is resilient, after repeated

impacts it continues to perform

|

Cost Savings

- Decreased damage cost by eliminating

surface damage

- Speed and Ease of application reduces

labor cost and increases productivity

- Ease of removal enhances customer

satisfaction

- Reduces inventory SKU’s by

providing a wide range of capabilities using same laminate wrap

- Conforms to product shape eliminating

the need for void fill and minimizing container size

- Economize by customizing package to

size required, using only what you need

- Lightweight packaging lowers transit

rates

|

|

|

|

|

|

|

|

|